Zogulitsa

Mtolo wachitsulo chosapanga dzimbiri kapena waya wamkati wamkati wopangira nsalu wa nsalu zotentha

Mafotokozedwe Akatundu

1-Stainless steel CHIKWANGWANI zochokera mtolo kumene awiri ulusi aliyense payekha ndi 12µ kapena 14µ. Kuchuluka kwa ulusi nthawi zambiri kumachokera ku 200 mpaka kupitilira 1500 ulusi. Izi zimakupatsani kulimba komwe kuli 'zabwino kwambiri m'kalasi'. Chifukwa cha ulusi wabwino womwe amagwiritsidwa ntchito, zingwezi zimakhalabe zopyapyala m'mimba mwake ndipo motero zimatha kusintha kwambiri pokonza.

2-Timaphimba ma waya owonjezera otsika komanso zingwe zazing'ono zokhala ndi mawonekedwe okhazikika komanso osinthika, mwapadera athu okhala ndi zingwe zazing'ono zamkati zamkati amatha kutsimikizira kukana pa mita yomwe mukufuna ndikukupatsani kusinthasintha kochulukirapo pamapangidwe koma kumakupatsani mwayi wabwinoko. flex-moyo kuposa wamba Cu-zingwe. Kutengera aloyi wakunja wokutidwa amene akhoza kukhala malata, mkuwa, aloyi siliva etc, tikhoza kupanga conductive kugonjetsedwa ngakhale m'munsi kuposa 1 ohm/m zingwe yaying'ono ndi mitundu limodzi ndi stranded malinga ndi kasitomala amafuna.

Ubwino wa zingwe zazing'ono zamkati za nsalu zamkati

Kupindika Kukana

Chifukwa cha kapangidwe kake ndi kuphatikiza kwa zinthu, waya amakhala ndi kukana kwabwino kopindika.

Kusinthasintha

Zingwe zazing'ono zimagwiritsa ntchito zojambulazo zachitsulo zowonda kwambiri ngati kondakitala, zomwe zimazindikira kusinthasintha kwakukulu.

Zabwino Kwambiri

Pambuyo extrusion chingwe chathu yaying'ono thinst akhoza kukhala 0.35mm.

Kuthamanga Kwambiri Kwambiri

Timagwiritsa ntchito ulusi wa Aramid / Liquid Crystal Polymer komanso ulusi waukadaulo wapamwamba kwambiri.

Kutentha Kwambiri. Kukaniza

Timagwiritsa ntchito ma aramid kapena zitsulo zosapanga dzimbiri zopangira ulusi, osagwira kutentha kwambiri kuchokera pa 230 mpaka madigiri 580 pazosankha zanu.

Kumaliza & kupaka

M'dziko lanu, nthawi zambiri pamafunika kuthira ulusi pawokha kapena kuphimba chingwe chonse. Titha kuchitanso, zomwe zili mkati mwathu zikuphatikizapo FEP,PFA,PTFE,TPU etc.

KUTULUKA KWA JACKET MAWU

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205 ° C | 255 ° C | 250 ° C |

| Cntchito mosalekeza Tufumu | 165 ° C | 205 ° C | 225 ° C |

Mitolo Yazitsulo Zosapanga dzimbiri

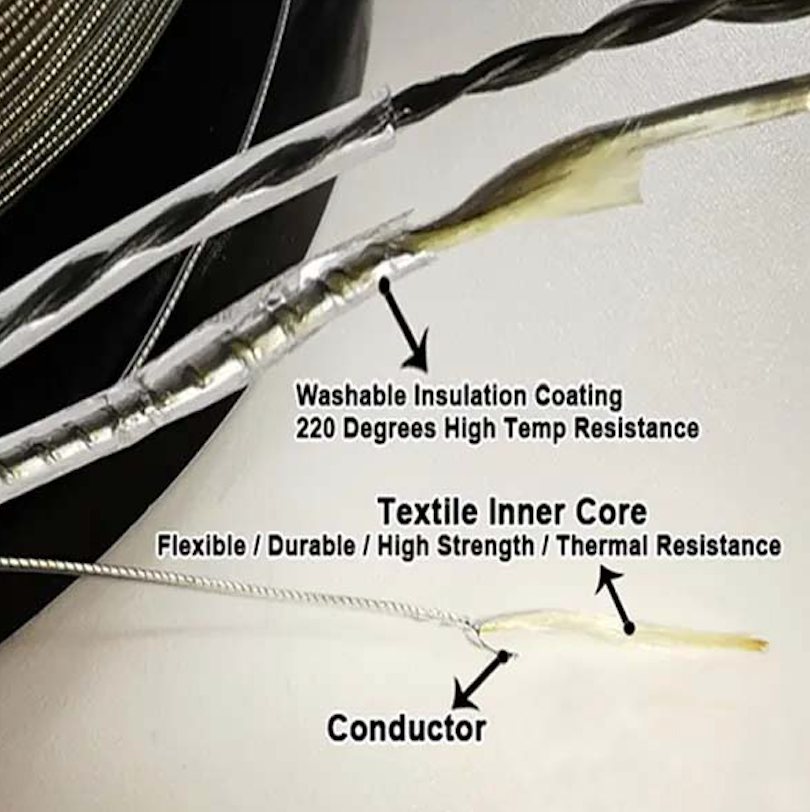

Zomangamanga za Textile Inner Core Micro Cable

Kutengera Embroided Heating Element

Chitsulo chosapanga dzimbiri chimaphatikiza milingo yosiyanasiyana yolimbana ndi zomwe mukufuna.

| Diameters (um) | Filaments | Mphamvu (cN) | Kulemera (g/m) | Kutalikira (%) | Kuthamanga (Ohm/m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100fx3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257f 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275fx2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275f ku 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275f 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275fx 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275x6 pa | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90fx2 pa | 46 | 0.190 | 1.10 | 44 |

| 14 | 90fx1 | 25 | 0.110 | 1.10 |

Waya wamkati wamkati wopangira nsalu amasiyanasiyana kukana

| Kondakitala Wakunja | Textile Inner Core | Diameter mm | Conductivity ≤Ω/m |

| Mkuwa 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| Mkuwa 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |

| Mkuwa 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Mkuwa 0.1mm | 200D Dinima | 0.22±0.02 | 4.00 |

| Mkuwa 0.1mm | 250D Polyester | 1 * 2/0.28 | 2.00 |

| Mkuwa 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| Mkuwa 0.05mm | 50D Polyester | 1*2/0.13 | 8.50 |

| Mkuwa 0.05mm | 70D Polyester | 0.11±0.02 | 12.50 |

| Mkuwa 0.55mm | 70D Polyester | 0.12±0.02 | 12.30 |

| Mkuwa 0.10mm | Thonje 42S/2 | 0.27±0.03 | 4.20 |

| Mkuwa 0.09mm | 150D Polyester | 0.19±0.02 | 5.50 |

| Mkuwa 0.06mm | 150D Polyester | 0.19±0.02 | 12.50 |

| Tin Copper 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Tin Copper 0.08mm | Zithunzi za 130D | 0.17±0.02 | 6.60 |

| Tin Copper 0.06mm | Zithunzi za 130D | 0.16±0.02 | 12.50 |

| Tin Copper 0.10mm | 250D Polyester | 0.23±0.02 | 4.00 |

| Tin Copper 0.06mm | 150D Polyester | 0.16±0.02 | 11.6 |

| Tin Copper 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Tin Copper 0.085mm | 150D Polyester | 0.19±0.02 | 6.00 |

| Silver Copper 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |